Products

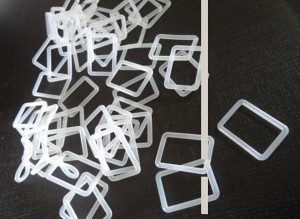

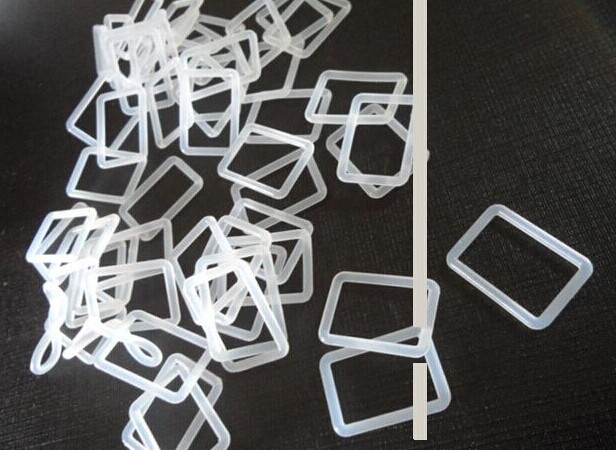

Sealing silicone ring Transparent silicone ring White square sealing ring for electrical appliances

The transparent square silicone sealing ring has the advantages of heat resistance, cold resistance, ozone resistance, and atmospheric aging resistance. Has very good electrical insulation properties. The tensile strength is worse than general rubber and it has no oil resistance.

advantage;

1. After formulating, the tensile strength can reach 1500PSI and the tear resistance can reach 88LBS

2. Good elasticity and good compression distortion

3. Good resistance to neutral solvents

4. With high heat resistance

5. With strong cold resistance

6. Resistant to the erosion of ozone and oxides

7. The electrical insulation performance

8. Good heat insulation and heat dissipation

Use range:

1. Seals or rubber parts used in the household appliance industry, such as electric kettles, electric irons, and rubber parts in microwave ovens.

2. Seals or rubber parts in the electronics industry, such as mobile phone keys, shock-absorbing pads in DVDs, and seals in cable joints.

3. Seals on all kinds of articles that are in contact with the human body, such as kettles, drinking fountains, etc.

The silicone seal ring adopts environmentally friendly imported silicone rubber raw materials, soft to the touch, wear-resistant and durable, and has good ductility, stable chemical properties, heat and cold resistance, and its physical properties are stretched. Environmentally friendly silicone

1. Use food grade (imported) silicone material

2. Various colors are available

3. The silicone rubber material used is elastic

4. According to customer needs, according to drawings and samples

l Butyl – A copolymer of isoprene of isobutylene, butyl is a synthetic rubber with several distinctive benefits. Butyl is impermeable to moisture and various gases, making it an ideal choice for airtight applications. With a service temperature range of -40°F to 225°F, this material has exceptional resistance to chemicals, abrasion, and diverse weather conditions. Butyl can easily adhere to other rubber materials, and it has great electrical insulation properties.

l EPDM – Ethylene propylene diene monomer, commonly known as EPDM, is an elastomer known for its high durability and versatility. EPDM has excellent resistance to heat, ozone, oxygen and oxygenated solvents, chemicals, animal and vegetable oils, and harsh weather. Stable in low and high temperatures, this material has a service range of -40°F to 250°F and is intermittent to 275°F. Additionally, EPDM can resist polar and steam substances with great proficiency.

l Natural (Pure Gum) – Natural rubber is a polymer consisting of isoprene. This soft material has high elasticity, which provides superior physical properties such as resistance to abrasion and low temperatures. Ideal for applications requiring acids, organic salts, and other chemicals, natural rubber is non-toxic and has a temperature range of -20°F to 170°F.

l Neoprene – Neoprene is a synthetic rubber created by polymerizing chloroprene material. Also called polychloroprene, neoprene is a flame-retardant material that can also resist the effects of oils, chemicals, oxygen, and ozone. For applications requiring higher tensile strength and ease of movement, cloth inserted neoprene is available; each variation can operate within the same -20°F to 170°F temperature range.

l Nitrile (NBR, Buna-N) – Nitrile is a copolymer of butadiene and acrylonitrile. This synthetic rubber material is resistant to various solvents, hydraulic fluids, animal and vegetable oils, and aromatic fuels; nitrile can also diminish the effects of heat aging. Nitrile performs optimally in temperatures ranging from -25°F to 170°F, and it is available in premium, commercial, and FDA grades.

l SBR – Styrene-butadiene rubber (SBR) has similar properties to natural rubber, but is more resistant to abrasion, wear, and hot and cold water. SBR has excellent adhesion to metals, and is available in red rubber and cloth inserted varieties; the latter is more proficient at handling movement, high compression loads, and saturated and low pressure steam. Each SBR variation can operate within the same -20°F to 170°F temperature range.

l Silicone – An extremely soft and adaptable material, silicone is composed of polymerized siloxanes. Silicone boasts superior elastomeric properties at both high and low temperatures and is resistant to the effects of ozone, oxygen, aging, ultraviolet (UV) light, and extreme weather conditions. Available in FDA grade, this material was a wide temperature service range of -67°F to 400°F and is intermittent to 450°F.

l Vinyl – Polyvinyl chloride (PVC) is a synthetic plastic polymer commonly used in applications with water or oxidizing agents. PVC material offers excellent resistance to abrasion and weather, and is available in rigid or flexible forms to suit various application needs. This material is ideal for temperatures ranging from 20°F to 160°F.

l Viton® – Known for its outstanding resistance to chemical substances, Viton® is a fluorocarbon-based synthetic rubber. This material can perform optimally in the most extreme conditions—Viton® has a maximum operating temperature from 400°F (continuous) to 500°F (intermittent). Additionally, this material can repel oxygen, ozone, various fuels and oils, solvents, and hydraulic fluids.

Most rubber, whether natural and synthetic, is also available in sponge form (cellular rubber) in both open and closed cell grades. Zichen Rubber offers neoprene, nitrile, silicone and Viton in sponge form. Closed cell sponge is available for applications requiring high compressibility, while open cell is available for cushioning applications where sealing is not an issue.

Using material sourced from domestic rubber manufacturers, ZICHEN keeps a large quantity of rubber materials in stock and can provide custom designs and shapes in varying grades, thicknesses and hardness to meet your specific needs.

ZICHEN GREAT SUCCESS RUBBER&PLASTIC CO.,LTD

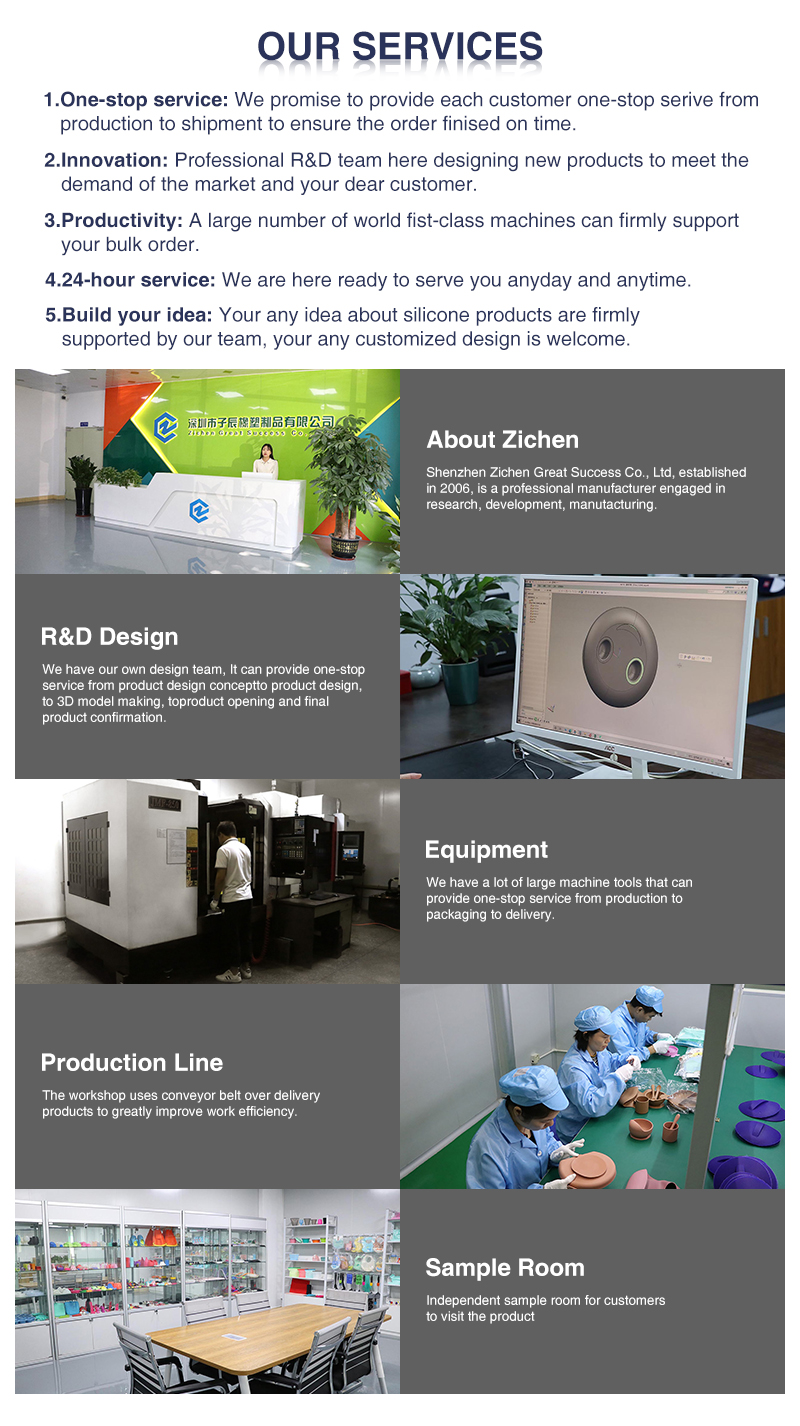

Company Profile

was established in 2002 and the factory is located in Shajing town, Shenzhen, south of China. It’s only half an hour drive to shenzhen airport. We specialize in manufacturing rubber, silicone and plastic products including daily life product, kitchenware, health care product, sex toy and children toy and custom parts applied in electric home appliance, automotive and spaceflight industries etc.,There are 200 employees in our factory and there are 20 staff in R&D department. We work together to establish very good business relationship with customers from all over the world.We have got ISO9001:2000 quality system certificate. The fifty percent of our products are exported to USA and Europe, Japan and south Asia. we also do OEM service and help customer to design and produce custom products according to the customers’ requirements .We hope to cooperate with all worldwide customers with quality products, competitive price and the best service.

Contact us for cheaper shipping

We provide custom services as below:

Excellent Service for E-commerce customers

Quick Shipping/Quality Assurance/Hot Sale/Nice Feedback

1. What is You Company Product Range?

chains. We provide one-stop service and welcome OEM and odm.

have received it. Each step of production and finished products will be carried out and inspection by QC before shipping.